Blog

The Recap We continue with the unfolding saga of the data science jobs landscape, this time for the month…

by Cherice

December 19, 2023

Blog

Cloud computing is now a commercial need rather than a competitive advantage in the era of Industry 4.0. To remain flexible, adaptable, and effective, manufacturing firms are adopting cloud-based solutions, from AI-powered analytics to smart factories. In this blog, we explore how cloud manufacturing is changing the manufacturing industry and helping businesses to cut expenses, improve efficiency, and boost innovation.

Let’s explore cloud based manufacturing with WeCloudData- The leading data and AI training academy

Cloud manufacturing is a business strategy in which manufacturing capabilities and resources are offered as cloud services. It facilitates the smooth integration of corporate systems such as ERP, MES, and PLM, as well as real-time data interchange, remote monitoring, and predictive maintenance. It is like typical cloud based computing, but specifically designed for industrial settings.

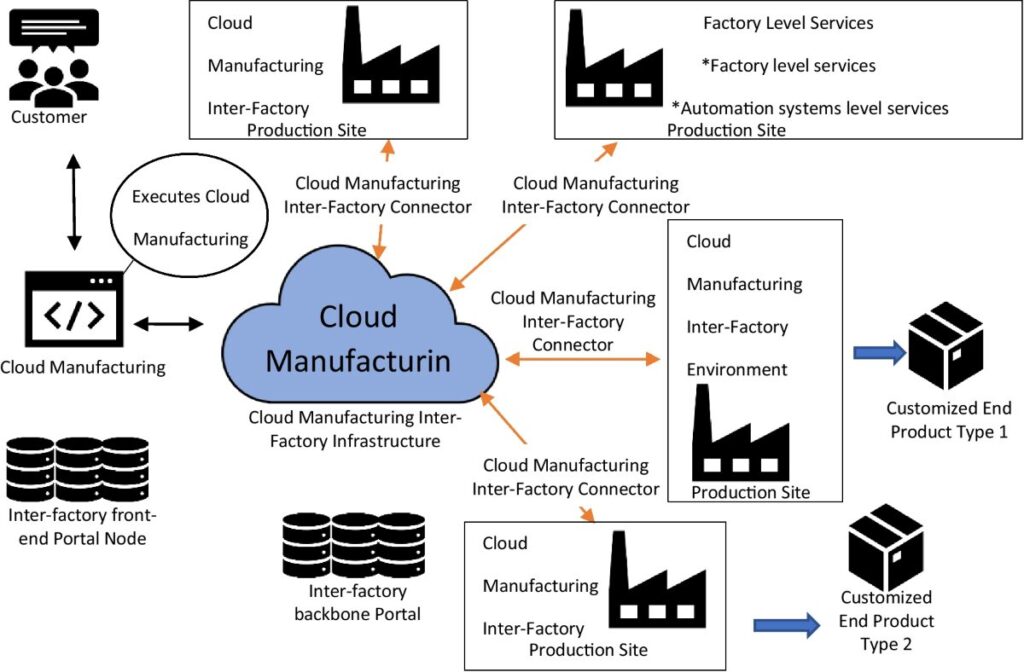

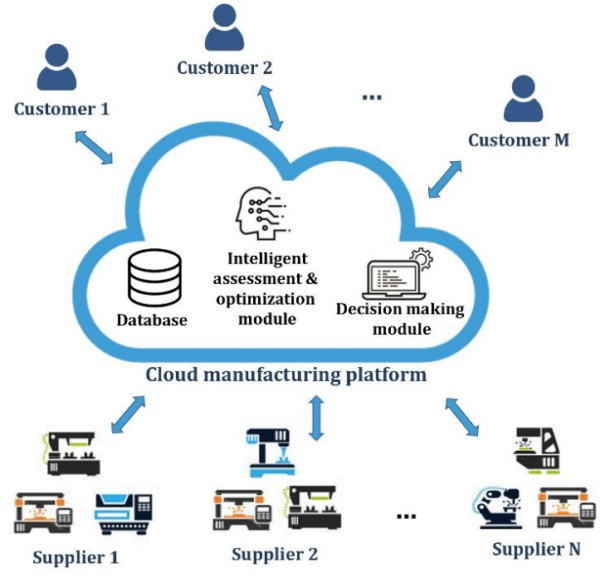

Cloud manufacturing works by linking devices, systems, and resources to the cloud, where they are virtualized and made available as services. Devices with Internet of Things capabilities provide data to a centralized cloud platform for analytics, decision-making, and real-time monitoring.

Manufacturers can remotely access tools and insights, integrate services like design, MES, and simulation, and collaborate across locations to improve efficiency, flexibility, and responsiveness.

Based on the demand, manufacturers can scale up or down their computing capabilities using cloud platforms like AWS, Microsoft Azure, and Google Cloud. Cloud services provide flexibility without the burden of infrastructure, whether starting a new manufacturing line or reacting to changes in the market.

The cloud manufacturing shifts the cost structure from capital expenditure (CapEx) to operational expenditure (OpEx). Manufacturers no longer need to invest heavily in on-premise IT hardware, ongoing maintenance, or upgrades because everything is available on a pay-as-you-go model.

Cloud-based technologies allow teams, suppliers, and partners throughout the world to collaborate in real time. Engineers can simultaneously access and modify product designs or production plans regardless of location, reducing errors and accelerating time-to-market.

Cloud manufacturing enables businesses to combine data from various sources, such as production lines, ERP systems, and Internet of Things devices, and use AI and data science methods to produce insights that can be put to use. This results in improved resource optimization, waste minimization, and forecasting.

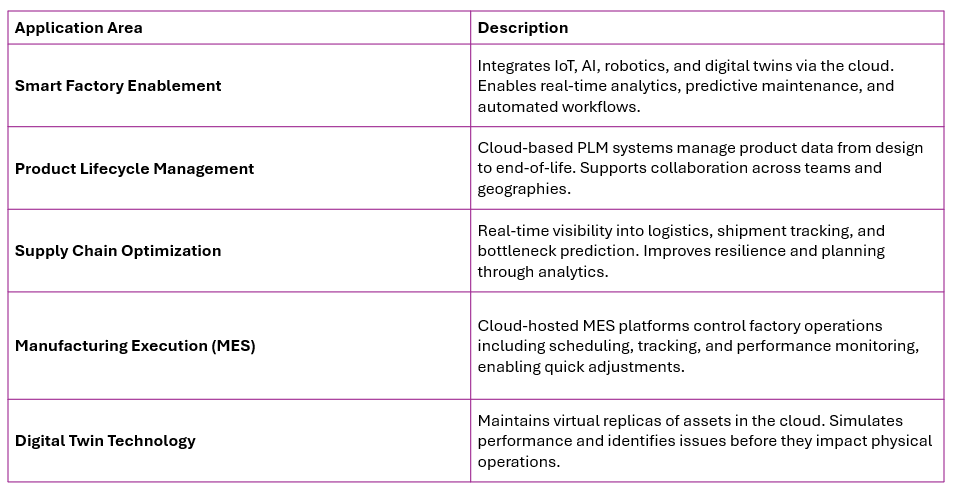

Cloud computing in manufacturing is actively transforming how factories operate across all levels. From real-time production monitoring to predictive analytics and global collaboration, cloud platforms enable manufacturers to digitalize and optimize every aspect of the value chain. Below are some of the most impactful application areas where cloud manufacturing is making a difference.

To fully leverage cloud technologies, companies must invest in training and certification for their workforce. With cloud systems touching everything from operations to analytics, having a skilled team is critical to successful implementation and scalability.

One of the leading programs for cloud upskilling is the WeCloudData Cloud Engineer Track, designed to equip professionals with hands-on skills in building, managing, and scaling secure multi-cloud environments.

The courses included in the cloud computing learning track include;

Visit WeCloudData to start your journey into Cloud Computing!

"*" indicates required fields

WeCloudData is the leading data science and AI academy. Our blended learning courses have helped thousands of learners and many enterprises make successful leaps in their data journeys.

"*" indicates required fields

Canada:

180 Bloor St W #1003

Toronto, ON, Canada M5S 2V6

US:

16192 Coastal Hwy

Lewes, DE 19958, USA